About Copper Conductor Submersible Pump Cables

We offer a high-quality range of Copper Conductor Submersible Pump Cables, specifically designed for power transmission in submerged conditions. These cables are ideal for deep well pump connections, agricultural water supply, and underground water pumping applications.

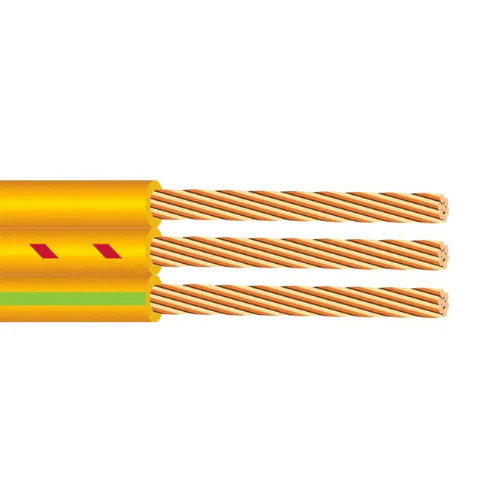

Manufactured using high-conductivity copper conductors, and insulated with PVC or XLPE, these cables are engineered for long-term performance under water. The flat construction ensures ease of installation and space-saving cable management.

Core Variants Offered:

-

2 Core and 3 Core Flat Cables

-

Sizes from 1.5 sq mm to 16 sq mm

-

Pure Copper Conductors (solid or stranded)

-

PVC or XLPE Insulation

-

Flat Design for Submersible Pump Use

Available in standard coil lengths. Custom specifications can be provided based on application.

Exceptional Durability and SafetyDesigned with flame retardant and moisture-resistant properties, these copper conductor submersible pump cables ensure protection against harsh conditions. The high-quality thermoplastic elastomer or PVC sheath shields cables from abrasion, chemicals, and oils, making them ideal for deep well installations. Insulation resistance exceeding 1 Mega ohm/km at 500V DC guarantees electrical safety.

Flexible and Customizable for Multiple ApplicationsOffering superior flexibility and a minimum bending radius of 12 times the cable diameter, these cables cater to installations in confined spaces and deep wells. With core options (2, 3, and 4), varied sizes (0.516 Sq.mm), and color customization, theyre suitable for agricultural, industrial, and domestic uses. Cables are available up to 500 meters, provided in coil or drum packing formats.

Reliable Power TransmissionBuilt with stranded or multistrand copper conductors and insulated with PVC/XLPE materials, the cables efficiently transmit power to submersible pumps. Supporting voltages up to 1100V and surges up to 1200V, they handle high starting currents required for pump operation. Testing up to 3.5 kV AC ensures robust performance at 50/60 Hz frequency.

FAQs of Copper Conductor Submersible Pump Cables:

Q: How do copper conductor submersible pump cables enhance safety in wet or abrasive environments?

A: With robust PVC or thermoplastic elastomer sheathing and superior insulation resistance, these cables offer reliable flame retardancy and strong resistance against moisture, abrasion, oil, and chemicals, ensuring safe operation in demanding settings.

Q: What are the recommended applications for these submersible pump cables?

A: These cables are suitable for submersible pump installations in deep wells, irrigation systems, agricultural sites, industrial locations, and domestic water supplies, providing dependable power transmission under varied environmental conditions.

Q: When is it necessary to use a cable with a high insulation resistance?

A: High insulation resistance is crucial in submersible applications to protect against electrical leakage and ensure operational safety when cables are consistently exposed to water and humidity.

Q: Where can these cables be installed and up to what depths?

A: They are designed for installation in deep wells, boreholes, and other submersible environments. Flexible construction allows them to be safely deployed to depths as required by standard pump specifications, depending on cable length up to 500 meters.

Q: What is the process for selecting the right cable size and core option?

A: Cable selection depends on the pumps electrical load, required current rating, installation environment, and application needs. Sizes range from 0.5 Sq.mm to 16 Sq.mm and come in 2, 3, or 4 core options to support various pump capacities and configurations.

Q: How can users benefit from customizable lengths and connector options?

A: Custom cable lengths (up to 500 meters) and open-end or tailored connector options streamline installation, minimize excess material, and ensure compatibility with pumps and control systems, reducing overall project costs.

Q: What advantage does the flexible design provide during installation?

A: High flexibility and a minimum bending radius of 12 times the cable diameter allow for easy handling and smooth deployment around bends or through narrow shafts, simplifying installation in wells and confined spaces.