Specification

- कनेक्टर टाइप

- Compatible with MC4 and other solar connectors

- तापमान

- सेल्सियस (oC)

- कोर की संख्या

- Single Core (also available in Twin Core)

- कंडक्टर का प्रकार

- Stranded (Class 5)

- प्रॉडक्ट टाइप

- AC and DC Solar Cable

- मटेरियल

- Copper Conductor, XLPE/LSZH Insulation

- फंक्शन

- Transmission of electrical power in solar systems

- उपयोग

- Connecting photovoltaic panels to inverter and other solar components

- वोल्टेज सर्ज

- Up to 1800V (DC)

- फ़्रिक्वेंसी (मेगाहर्ट्ज)

- हर्ट्ज (एचजेड)

- रेटेड वोल्टेज

- वोल्ट (V)

- इन्सुलेशन सामग्री

- UV Resistant XLPE, Electron Beam Cross-linked Polyolefin

- कंडक्टर सामग्री

- Tinned Copper

- लम्बाई

- मिलीमीटर (mm)

- साइज

- 1.5 sq.mm to 16 sq.mm

- रंग

- Red, Black (others on request)

- व्यास

- मिलीमीटर (mm)

- एप्लीकेशन

- PV power installations, solar farms, rooftop systems

- Oil Resistance

- Yes

- Mechanical Strength

- High tensile strength with low resistance

- Jacket Material

- Black UV-resistant polyolefin

- Fire Performance

- Flame retardant, Halogen Free

- Ozone Resistance

- Yes

- Minimum Bending Radius

- 5 x Cable outer diameter

- Standards Compliance

- EN 50618, TUV 2PfG/1169, IEC 62930

- Test Voltage

- 6500V (AC)

- UV Resistance

- Excellent (for outdoor use)

- Insulation Resistance

- >2000 MΩ·km

- Flexibility

- High

Trade Information

- Minimum Order Quantity

- 50 Meter

- डिलीवरी का समय

- दिन

- मुख्य घरेलू बाज़ार

- , ,

About

We offer a premium range of AC and DC Solar Cables designed to cover the full spectrum of solar power transmission from solar photovoltaic modules to inverters, and from inverters to the grid or load center. These cables are manufactured with high-quality copper conductors (tinned or plain) to ensure superior conductivity, UV resistance, and long-term performance in harsh outdoor environments.

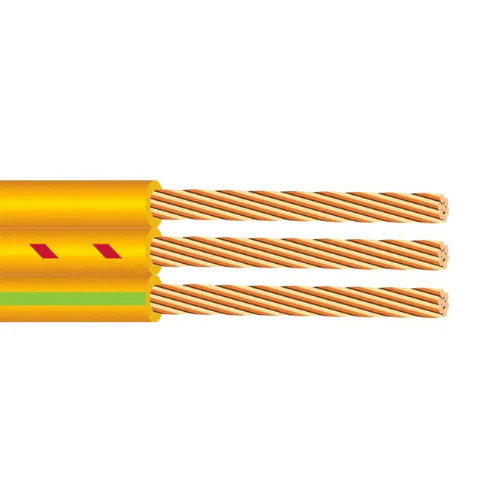

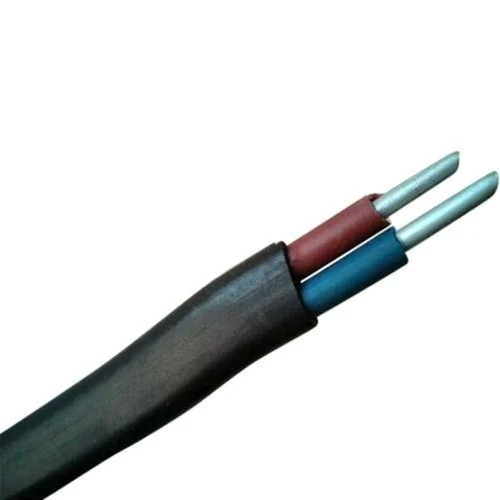

Our cables are available in single core, twin core, and multi-core constructions, with insulation and sheathing options such as XLPO, XLPE, PVC, and FRLS, all engineered to be flame-retardant and weather-resistant.

We also offer pre-terminated DC extension cables with MC4 connectors for quick and reliable solar connections.

Available Variants:

DC Solar Cables:

-

1.5 kV Single Core, Tinned Copper, XLPO Insulated, UV Resistant

-

1.5 kV Single Core, Copper, XLPE Insulated, Flame Retardant

-

1.8 kV Single Core, Tinned Copper, XLPO, Halogen-Free, EB Cross-Linked

-

1.5 kV Twin Core, Copper, PVC Insulated, UV Resistant

-

2.0 kV Single Core, Flexible Copper, Double Insulated XLPO Sheath

-

1.5 kV Single Core, XLPO Insulated, Fire-Resistant (EN 50618 / IEC 62930)

-

Pre-Terminated DC Extension Cables with MC4 Connectors, UV/Weather Resistant

AC Solar Cables:

-

1.1 kV Single Core, Copper, XLPE Insulated, PVC Sheathed

-

1.1 kV 3 Core, Copper, XLPE Insulated, FRLS Outer Sheath

-

1.1 kV 4 Core, Copper, XLPE Insulated, Weatherproof PVC Sheath

-

3.3 kV Single Core, Copper, XLPE Insulated, Armoured, UV Resistant

-

1.1 kV Flexible Multi-core Copper, PVC/FRLS Insulated for Indoor AC Use

-

1.1 kV Twin Core, Copper, XLPE Insulated, Flame Retardant Sheath

-

Armoured AC Cables with XLPE Insulation and FRLS Sheath for Industrial Applications

High Standards Compliance & Safety

Designed in accordance with global standards like EN 50618, TUV 2PfG/1169, and IEC 62930, our cables guarantee safety and consistent performance. Flame retardant and halogen-free properties make these cables suitable for critical environments, while mechanical resilience assures effective power transmission even in rigorous conditions.

Outstanding UV & Ozone Resistance

Equipped with a black UV-resistant polyolefin jacket and advanced insulation technology, these cables withstand harsh sunlight and ozone exposure. They are crafted specifically for extended outdoor use in solar farms and rooftop installations, ensuring long-term reliability and reduced maintenance costs.

Flexible & Durable Construction

High flexibility and strong mechanical properties enable easier routing and installation, regardless of the project complexity. Our stranded tinned copper conductors and specialized insulation materials provide lasting durability, supporting voltage surges up to 1800V (DC) and accommodating varying current loads efficiently.

FAQs of AC and DC Solar Cable:

Q: How should AC and DC solar cables be installed in photovoltaic systems?

A: AC and DC solar cables should be laid in accordance with the specified minimum bending radius5 times the cables outer diameterto maintain integrity. Ensure proper connection to MC4 or compatible solar connectors, avoiding excessive tension or sharp bends. Always follow applicable installation standards.Q: What makes the cable suitable for Indian outdoor solar projects?

A: The cables black UV-resistant polyolefin jacket, excellent ozone resistance, and flame-retardant, halogen-free insulation make it ideal for Indias climate conditions, especially in solar farms and rooftop installations. Its reliability under high temperatures and sunlight ensures dependable, long-term performance outdoors.Q: When is a custom cable length required for photovoltaic installations?

A: Custom cable lengths are typically needed when the distance between panels, inverters, and other solar components differs from standard reel sizes (100m/200m). Tailored cable lengths help minimize wasted material and ensure efficient connections specific to the projects design layout.Q: Where can these solar cables be used?

A: These cables are designed for PV power installations, including large solar farms, rooftop systems, and distributed solar generation environments. Their high mechanical strength and flexibility also allow safe use in commercial and industrial solar projects across varied locations.Q: What process is used for enhanced insulation and durability?

A: The cables use electron beam cross-linked polyolefin for insulation, providing high mechanical strength and superior thermal stability. XLPE/LSZH insulation ensures resistance to fire, oils, and chemicals, while protecting against voltage surges and environmental factors.Q: Why is tinned copper used as the conductor material?

A: Tinned copper offers excellent conductivity and resists oxidation, making it ideal for outdoor environments. It ensures stable current transmission, reduces maintenance needs, and extends the cables lifespan in demanding solar installations.Q: How does using these cables benefit PV installations?

A: Utilizing these high-quality, compliant solar cables results in safer electrical transmission, reduced installation complexity, greater longevity, and lower operating costs. Their robust design supports dependable power flow, essential for maximizing energy yield and system reliability in solar projects.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in एल्यूमीनियम तार Category

बेयर एल्युमिनियम वायर

मूल्य की इकाई : मीटर

न्यूनतम आदेश मात्रा : 100

माप की इकाई : मीटर

उपयोग : औद्योगिक

साइज : विभिन्न आकार

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese